HWQZ series intelligent turbine gas flowmeter integrates turbine gas flow sensor and high-performance volume corrector, directly detecting and displaying operation condition volume flow, standard volume flow and total volume. The product adopts high-performance pressure and temperature sensors, new type high-frequency flow signal module, featured with high accuracy, good repeatability, mature and stable technology. NB-IoT/GPRS module can be embedded to realize wireless data transmission. The flowmeter is suitable for the measurement of various single-phase gases and is an ideal product for gas measurement in urban gas, petroleum, chemical, electric power, and metallurgy industries etc.

This product complies with GB/T 18940-2003/ISO 9951:1993 Measurement of Gas Flow in Closed Conduits - Turbine Meters and the national standard and calibration procedures JJG 1037-2008 Turbine Flow Meters. The overall performance of the product is superior and the main technical indicators have reached the international advanced level.

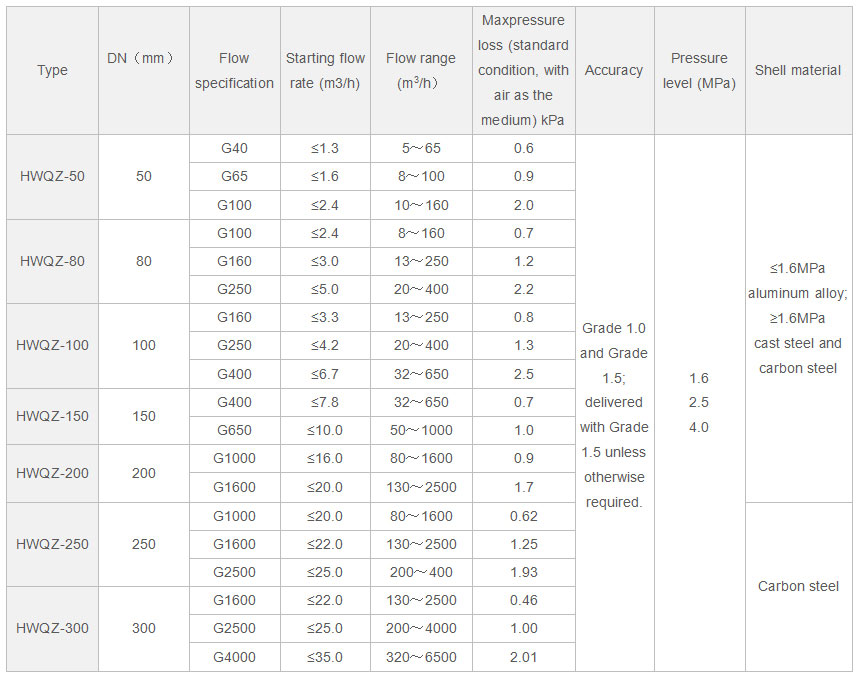

Low pressure loss, high precision, good repeatability, low starting flow rate and wide measuring range.

Adopting integrated two-stage rectifier. Low requirements for straight length (front >2DN, back >1DN).

Designed with the independent machine core, good interchangeability and easy maintenance.

Adopting precision bearings for exclusive use of instruments imported from Europe, with flexible rotation and high durability.。

Adopting the well-designed reverse-driving structure and unique sealing structure, and the bearing runs stably for a long period.

Strict dynamic balance test to ensure working stability and service life of the product.

The intelligent volume corrector is free to rotate by 340° and is easy to read in various installation positions.

Adopting high-performance CPU and modern digital filtering technology, with powerful software and superior performance.

The circuit system adopts micro power consumption design, with built-in battery for power supply; in addition, an external power supply can also be adopted.

Integrating the flowmeter sensor and the volume corrector, it can detect the temperature, pressure and compression factor of the measured gas for automatic tracking and correction, directly detecting or measuring the standard condition volume flow and total amount of the gas.

The LCD screen displays the standard cumulative flow rate, standard volume flow rate, volume flow rate under working conditions, medium temperature, absolute pressure and battery capacity percentage, etc., with prompt in both Chinese and English.

There are three kinds of historical data records: start and stop records, status records, and daily records, which are convenient for users to query and count the gas consumption.

It has real-time data storage function to prevent data loss when battery is replaced or suddenly power-off; internal parameters and historical data records can be permanently saved in power-off state.

With data tamper prevention and automatic key data modification recording functions.

Provided with RS-485 communication interface for matching with a dedicated data acquisition unit, forming a remote data acquisition and monitoring system via NB-IoT/GPRS, which facilitates centralized data acquisition and real-time management.

Configured with two-wire 4-20mA standard current signal output for easy connection with secondary instruments.

With built-in lightning protection, anti-surge, pulse group suppression and other protection circuits, the external transmission interface is electrically isolated with strong anti-interference performance and high reliability.

Explosion-proof function, explosion-proof mark: Exib II BT4 Gb.